How to Choose a Diesel Generator

When choosing a diesel generator, it's important to consider performance, usage, environment, and cost. Here are key considerations:

1. Clarify Your Needs

Power Demand: Calculate the total load power (starting current + running power) and reserve 10%-20% margin to avoid overloading.

Distinguish between backup power (short-term use) and regular power (long-term operation), with the latter requiring higher specifications.Usage Scenario: Different usage scenarios (e.g., construction sites, hospitals, data centers) have varying stability requirements. Hospitals need a quick start (e.g., within 10 seconds), while construction sites can opt for low-noise mobile models.

2. Generator Types

Open-Type: Lower cost but requires a separate room.

Silent-Type (60-75 decibels): Suitable for residential areas.

Mobile-Type: Convenient for movement, suitable for mobile needs.

Single-phase: Suitable for household low power (220V).

Three-phase: Suitable for industrial use (380V).

3. Key Parameters

Engine Brand: Prefer brands like Cummins, Perkins, Volvo, Yuchai for durability and reliable after-sales service.

Generator Efficiency: Check the fuel consumption rate (e.g., below 200g/kWh) for fuel-efficient models.

Voltage Stability: The voltage fluctuation range should be ≤±5%. Precision equipment may require an automatic voltage regulator (AVR).

4. Environmental & Compliance Considerations

Emission Standards: Choose a product that meets the emission standards of your country.

Noise Control: Choose models with ≤65 decibels for residential areas; industrial areas can tolerate up to 75 decibels.

5. Key Configurations

Control System: Automatic transfer switch (ATS) functionality is crucial for key facilities like hospitals. Remote monitoring is ideal for unmanned scenarios.

Cooling System: Air cooling is suitable for low power (<20kW); water cooling is ideal for high power and long-term operation.

Fuel System: A multi-stage filtration system helps extend engine life, especially in low-quality diesel environments.

6. Installation & Maintenance

Installation Conditions: The generator room should be ventilated and moisture-proof, with a vibration-damping base. A rain cover is required for outdoor installation.

Maintenance Costs: Check the compatibility and price of accessories (such as filter cartridges and batteries) to avoid high prices for proprietary accessories.

7. Supplier Evaluation

Certifications and After-Sales Service: Confirm that the supplier has ISO certifications, warranty periods, and local service centers.

8. Cost Analysis

Compare initial costs with lifecycle costs. Low-quality models may have poor fuel efficiency or high failure rates, leading to higher maintenance costs in the long run.

9. Common Pitfalls

False power ratings: Confirm the difference between prime power and standby power.

Refurbished machines: Request original manufacturer certification and check the engine serial number.

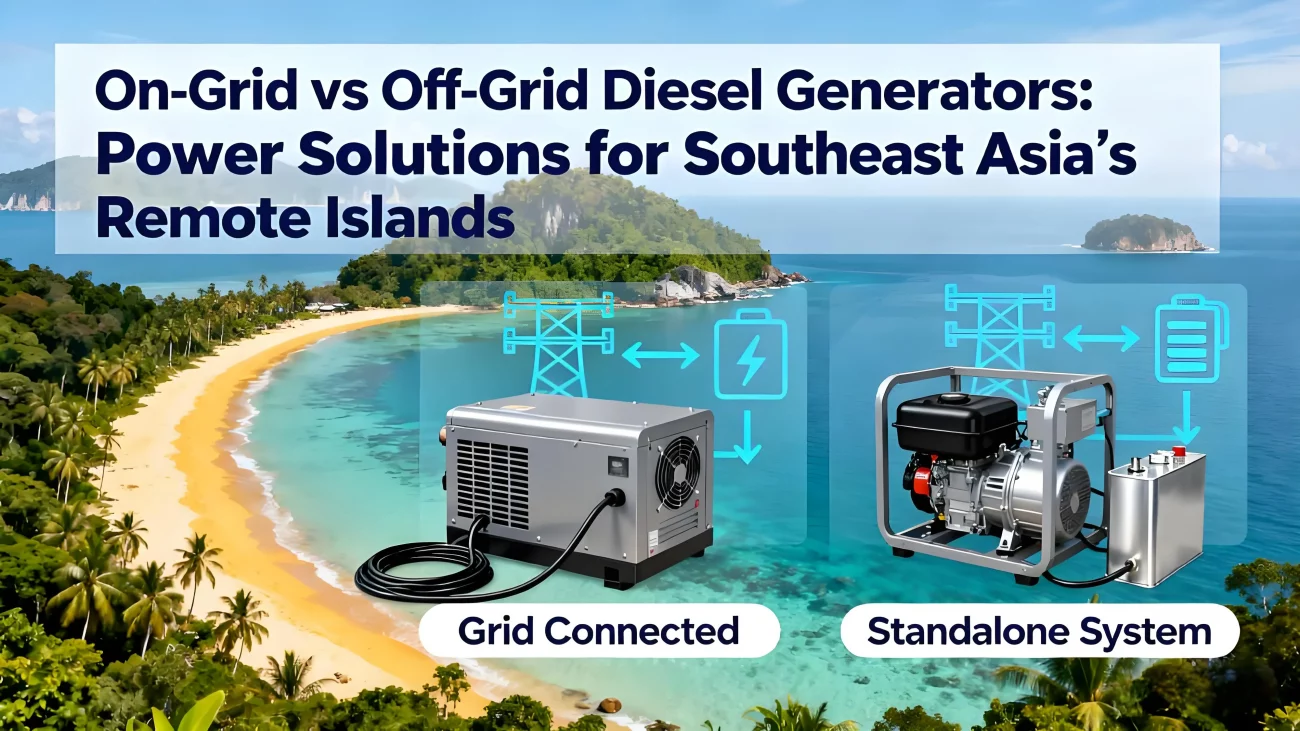

Compatibility: If grid connection is required, confirm in advance that the inverter is compatible.

10. Recommended Purchase Steps

List all load power requirements and calculate the total demand.

Select the types (silent/mobile/fixed) based on the usage scenario.

Compare parameters from 3-5 brands, focusing on engine and control systems.

Test a sample unit on-site, checking noise levels, emissions, and voltage stability.

Ensure the contract clearly defines warranty terms and delivery time.

By systematically evaluating the above factors, you can select a diesel generator that offers high cost performance and meets your needs. If you have special requirements (such as high altitude or extremely cold environments), please consult DC for a customised solution.